1. Environmental performance: zero emissions and low noiseZero exhaust emissionsThe lithium battery pruning shears are powered by lithium batteries and do not produce harmful gases such as CO ₂ and NO...

READ MORECATEGORIES

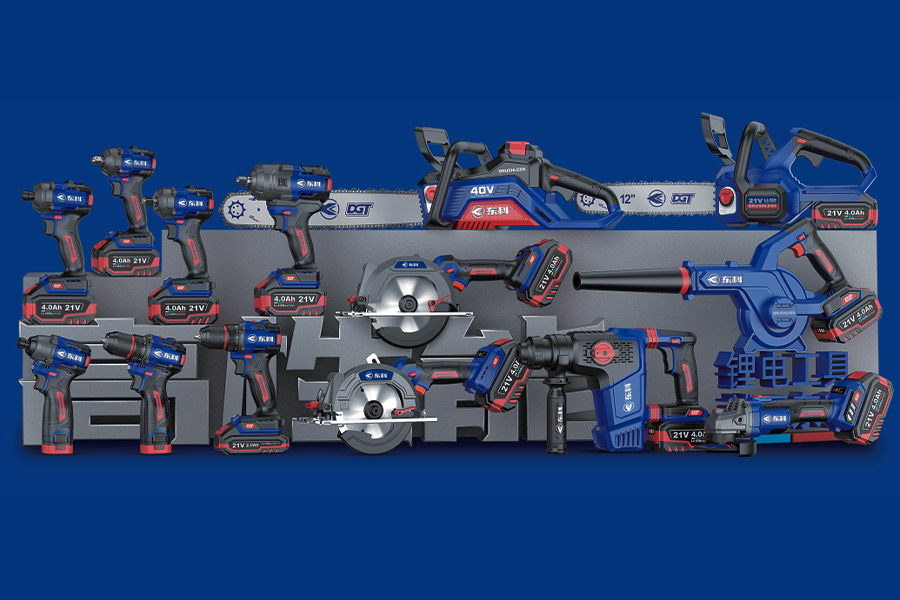

Lithium Cordless Circular Saw Manufacturers

-

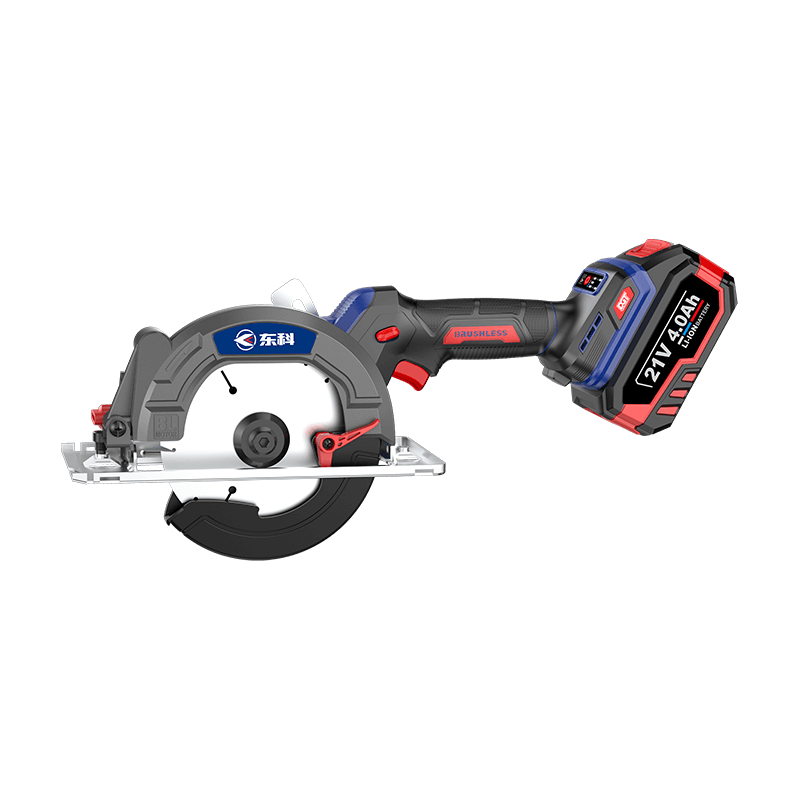

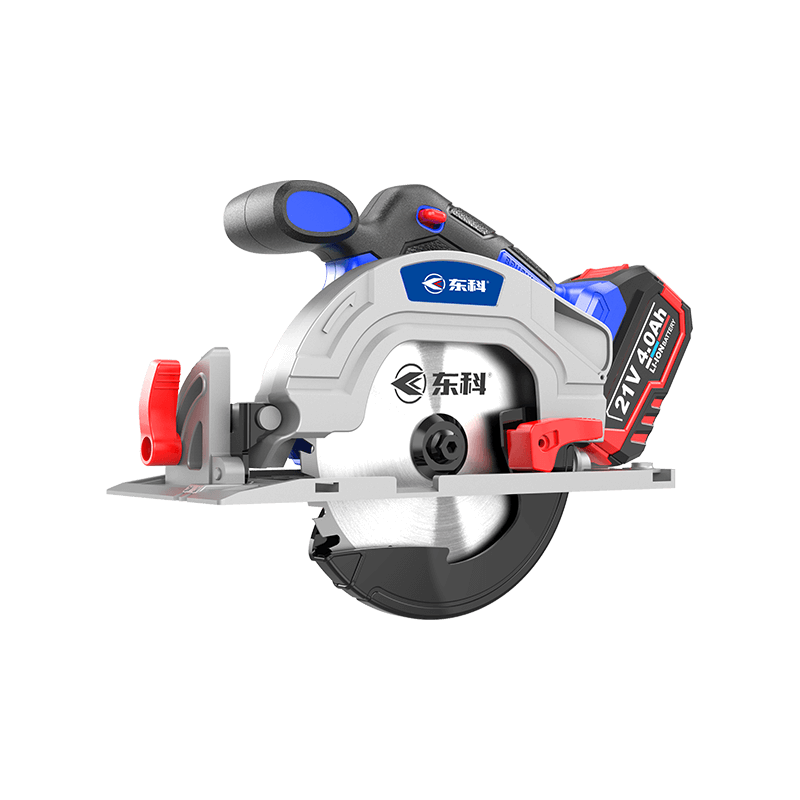

DGTO-1610B

DGTO-1610B

Woodworking 5.5 inches rechargeable electric circular saw , single hand saw

-

DGTO-1610B

DGTO-1610B

6.5 Inches woodworking electric circular saw,portable hand saw

The compact, lightweight design of our lithium cordless circular saw allows for easy maneuvering and operation even in tight spaces. With the lithium-ion battery pack, users can enjoy longer runtimes and faster recharge times, ensuring that downtime is minimized during intense projects.

Equipped with a high-speed motor, razor-sharp and durable carbide blades, and an adjustable depth of cut, our lithium cordless circular saw easily cuts through a variety of materials, including wood, plastic and so on. Whether crosscutting lumber for framing or making precise rip cuts, this tool delivers accurate, clean results with ease.

Our lithium cordless circular saw is equipped with an electric brake that stops the blade almost immediately after the trigger is released, preventing accidents. Additionally, the integrated blade guard provides a protective barrier over the cutting edge, reducing the risk of injury during handling.

Comfort and ergonomics were key design considerations. The soft handle and well-balanced structure ensure that users can work long hours without hand fatigue.

lithium cordless circular saw are extremely portable, enabling users to tackle projects in remote locations or areas where electricity is not readily available.

About Us

Nantong Dongke Tools Co., Ltd.

Nantong Dongke Tools Co., Ltd is a China OEM Lithium Cordless Circular Saw Manufacturers and ODM Lithium Cordless Circular Saw Factory and trade, committed to research and development, manufacturing, and sales of charging tools and spare parts. The company is located in the "China power tool manufacturing base", the Yangtze River Delta economic important area - Haimen Port New District, Jiangsu Province.

Since its establishment, the company has continuously introduced advanced technology and equipment domestically and abroad and accumulated a lot of technical talents engaged in the research and development, design, and production of charging tools. We specialize in custom Lithium Cordless Circular Saw sale, The company integrates product research and development, design, production, and sales, providing a full range of nickel-cadmium charging drills, lithium charging drills, batteries, chargers, and other high-quality and reliable products. Strive to provide customers with quality products and services, the company's production of lithium batteries domestic and international customers unanimous recognition and praise!

Since its establishment, the company has continuously introduced advanced technology and equipment domestically and abroad and accumulated a lot of technical talents engaged in the research and development, design, and production of charging tools. We specialize in custom Lithium Cordless Circular Saw sale, The company integrates product research and development, design, production, and sales, providing a full range of nickel-cadmium charging drills, lithium charging drills, batteries, chargers, and other high-quality and reliable products. Strive to provide customers with quality products and services, the company's production of lithium batteries domestic and international customers unanimous recognition and praise!

News

-

-

1. Maintenance points Cleaning and rust preventionAfter using the lithium reciprocating saw, the dust and moisture around the blade should be cleaned in time to prevent rust and malfunction. Pay speci...

READ MORE -

1. Impact energy and drilling diameterThe impact energy (in joules/J) determines the penetration force.The upper limit of drilling diameter needs to match the actual requirements. 2. Motor and battery...

READ MORE

Lithium Cordless Circular Saw Industry knowledge

The Environmental Benefits of Lithium Cordless Circular Saws

Lithium cordless circular saws offer several environmental benefits compared to their traditional counterparts. Here are some of the key environmental benefits:

1. Reduced carbon emissions: Lithium cordless circular saws are battery-powered, eliminating the need for gasoline or diesel fuel. This means they do not emit any greenhouse gases or contribute to air pollution when in use. By using a lithium cordless circular saw, you can significantly reduce your carbon footprint and contribute to a cleaner environment.

2. Noise reduction: Traditional circular saws powered by gasoline or electricity tend to be very noisy, causing noise pollution. In contrast, lithium cordless circular saws operate quietly, reducing noise levels both for the user and those in the surrounding area. This can be particularly beneficial in residential or urban areas where noise pollution can be a significant concern.

3. Energy efficiency: Lithium batteries used in cordless circular saws are known for their high energy efficiency. They can store a significant amount of energy and deliver it to the tool efficiently, resulting in less energy waste. In comparison, traditional circular saws powered by electricity may experience energy loss during transmission from the power source to the tool.

4. Reduced wastage: Traditional circular saws often require the use of disposable batteries, which contribute to landfill waste. Lithium cordless circular saws, on the other hand, use rechargeable lithium batteries that can be charged and reused multiple times. This reduces the amount of battery waste generated and helps conserve valuable resources.

5. Mobility and versatility: Lithium cordless circular saws offer greater mobility compared to corded electric saws. You can use them in remote locations or areas without a readily available power supply. This mobility can reduce the need to transport materials to a central location, minimizing the environmental impact associated with transportation.

Slicing Through Plywood: A Step-by-Step Guide to Using Your Lithium Cordless Circular Saw

Using a lithium cordless circular saw can be a convenient and efficient way to cut through plywood. Here is a step-by-step guide to help you use your tool effectively:

Step 1: Safety precautions

Before starting, always remember to wear appropriate safety gear, such as safety goggles and work gloves, to protect your eyes and hands from flying debris.

Step 2: Set up your workspace

Ensure you have a stable work surface to place the plywood on. It's also a good idea to firmly secure the plywood using clamps or other holding mechanisms to prevent it from moving during the cutting process.

Step 3: Adjust the saw

Most cordless circular saws allow you to adjust cutting depth and angle. Set the desired cutting depth based on the thickness of the plywood. If required, adjust the cutting angle as well.

Step 4: Position the plywood

Place the plywood on the work surface so that the area you intend to cut is not hanging off the edge. It should be supported entirely on the surface.

Step 5: Align the blade

Position the saw so that the blade is aligned with the cutting line you've marked on the plywood. Make sure the blade is not touching the plywood at this point.

Step 6: Start the saw

Following the manufacturer's instructions, start the cordless circular saw. Allow it to reach its full speed before starting the cut.

Step 7: Make the cut

With a firm grip on the saw, slowly lower the blade onto the plywood, ensuring that it's aligned with the cutting line. Apply gentle pressure and let the saw do the cutting. Avoid forcing the blade through the plywood, as it may result in a rough or uneven cut.

Step 8: Maintain control

Maintain a steady and controlled movement of the saw throughout the cutting process. Follow the cutting line, and keep your hands and fingers away from the blade and the cutting area.

Step 9: Complete the cut

Once you've reached the end of the cutting line, allow the blade to come to a stop before lifting the saw off the plywood. Do not remove the blade from the plywood until it has completely stopped moving.

Step 10: Clean up

After cutting, remove any debris or sawdust from the work area. This will provide a clear workspace for any additional cuts or other tasks.

Remember to always handle your lithium cordless circular saw with caution and refer to the manufacturer's guidelines for specific operating instructions.

Lithium cordless circular saws offer several environmental benefits compared to their traditional counterparts. Here are some of the key environmental benefits:

1. Reduced carbon emissions: Lithium cordless circular saws are battery-powered, eliminating the need for gasoline or diesel fuel. This means they do not emit any greenhouse gases or contribute to air pollution when in use. By using a lithium cordless circular saw, you can significantly reduce your carbon footprint and contribute to a cleaner environment.

2. Noise reduction: Traditional circular saws powered by gasoline or electricity tend to be very noisy, causing noise pollution. In contrast, lithium cordless circular saws operate quietly, reducing noise levels both for the user and those in the surrounding area. This can be particularly beneficial in residential or urban areas where noise pollution can be a significant concern.

3. Energy efficiency: Lithium batteries used in cordless circular saws are known for their high energy efficiency. They can store a significant amount of energy and deliver it to the tool efficiently, resulting in less energy waste. In comparison, traditional circular saws powered by electricity may experience energy loss during transmission from the power source to the tool.

4. Reduced wastage: Traditional circular saws often require the use of disposable batteries, which contribute to landfill waste. Lithium cordless circular saws, on the other hand, use rechargeable lithium batteries that can be charged and reused multiple times. This reduces the amount of battery waste generated and helps conserve valuable resources.

5. Mobility and versatility: Lithium cordless circular saws offer greater mobility compared to corded electric saws. You can use them in remote locations or areas without a readily available power supply. This mobility can reduce the need to transport materials to a central location, minimizing the environmental impact associated with transportation.

Slicing Through Plywood: A Step-by-Step Guide to Using Your Lithium Cordless Circular Saw

Using a lithium cordless circular saw can be a convenient and efficient way to cut through plywood. Here is a step-by-step guide to help you use your tool effectively:

Step 1: Safety precautions

Before starting, always remember to wear appropriate safety gear, such as safety goggles and work gloves, to protect your eyes and hands from flying debris.

Step 2: Set up your workspace

Ensure you have a stable work surface to place the plywood on. It's also a good idea to firmly secure the plywood using clamps or other holding mechanisms to prevent it from moving during the cutting process.

Step 3: Adjust the saw

Most cordless circular saws allow you to adjust cutting depth and angle. Set the desired cutting depth based on the thickness of the plywood. If required, adjust the cutting angle as well.

Step 4: Position the plywood

Place the plywood on the work surface so that the area you intend to cut is not hanging off the edge. It should be supported entirely on the surface.

Step 5: Align the blade

Position the saw so that the blade is aligned with the cutting line you've marked on the plywood. Make sure the blade is not touching the plywood at this point.

Step 6: Start the saw

Following the manufacturer's instructions, start the cordless circular saw. Allow it to reach its full speed before starting the cut.

Step 7: Make the cut

With a firm grip on the saw, slowly lower the blade onto the plywood, ensuring that it's aligned with the cutting line. Apply gentle pressure and let the saw do the cutting. Avoid forcing the blade through the plywood, as it may result in a rough or uneven cut.

Step 8: Maintain control

Maintain a steady and controlled movement of the saw throughout the cutting process. Follow the cutting line, and keep your hands and fingers away from the blade and the cutting area.

Step 9: Complete the cut

Once you've reached the end of the cutting line, allow the blade to come to a stop before lifting the saw off the plywood. Do not remove the blade from the plywood until it has completely stopped moving.

Step 10: Clean up

After cutting, remove any debris or sawdust from the work area. This will provide a clear workspace for any additional cuts or other tasks.

Remember to always handle your lithium cordless circular saw with caution and refer to the manufacturer's guidelines for specific operating instructions.

English

English русский

русский Español

Español عربى

عربى 中文简体

中文简体